CLIMB Aluminum Plate Creates Marine Ranch

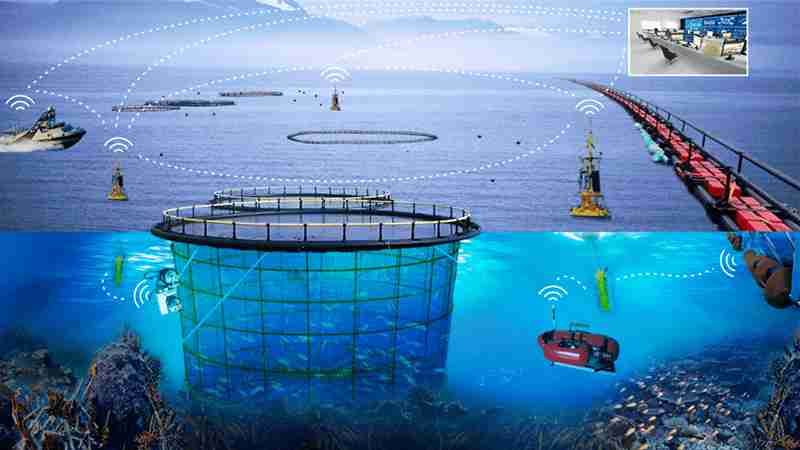

Marine ranching is a kind of platform for artificial cultivation of marine organisms floating on the offshore water. Combine the functions of fishery breeding, marine tourism, scientific and technological research and development, improve the efficiency of fishery breeding with scientific and technological innovation, and realize the transformation and upgrading of marine fishery. Equipped with automatic feeding, environmental monitoring, ship anti-collision and other systems as well as unmanned ships, underwater patrol robots and other technical equipment, the whole production process can be intelligently controlled. CLIMB Aluminum Plate Creates Marine Ranch

Among the metal materials used to build the marine ranch, more than 75% of the superstructure and internal structure are made of aluminum. Because of the small density of aluminum, the quality of the structure can be greatly reduced. At the same time, aluminum has a strong corrosion resistance to seawater and marine atmosphere. It can be said that the marine ranch should be all aluminum. The so-called all aluminum does not mean that all structural members are made of aluminum or aluminum alloy. On the premise of meeting technical performance requirements and ensuring safety and environmental protection, all workpieces that can be made of aluminum or aluminum alloy should be aluminum or aluminum alloy.

The corrosion of aluminum alloys is more serious than that of pure aluminum, but there are a few exceptions. The corrosion resistance of aluminum and aluminum alloys in air, acid and water is arranged in descending order as follows: Al, AI-Mn alloy, Al-Mg alloy, Al-Mg-Si alloy, Al-Si alloy, Al-Zn-Mg alloy, Al-Zn-Mg alloy, Al-Cu-Mg alloy, Al-Cu-Mg alloy. The descending order in alkaline solution and seawater is: Al-Mg alloy, Al, Al-Mn alloy, Al-Mg-Si alloy, Al-Zn-Mg alloy, Al-Si alloy, Al-Zn-Cu-Mg alloy, Al-Cu-Mg alloy, Al-Cu alloy. It should be noted that the above order of corrosion resistance can be established only when the alloys sensitive to exfoliation corrosion, intergranular corrosion or stress corrosion cracking are heat treated and these sensitivities are removed. At the same time, the above arrangement is only a rough order, and under special circumstances, there may be some changes. The corrosion resistance of aluminum clad material is only slightly worse than that of aluminum clad layer, for example, the corrosion resistance of AI Cu alloy coated with pure aluminum is equal to or even better than that of AI Mn alloy.

It can be seen from the above introduction that Al-Mg series alloys, namely 5XXX (5000) series aluminum alloys, are the best metal materials for manufacturing marine equipment, because they have both the highest resistance to marine environmental corrosion and the lowest density of aluminum alloys, which is extremely beneficial to reduce the self weight of products such as the “Genghai No.1” marine ranch complex platform. Due to the high corrosion resistance of AI Mg series, the aluminum alloy platform does not need to be maintained for life (30 years), while the steel platform must be maintained every three to five years, otherwise it will be rusty.

Among the 105 commonly used AI Mg alloys registered by the American Aluminum Association (AA), Climb recommends 5182, 5454, 5083, 5086, and 5052 as the best alloys because they have the best comprehensive properties. At present, all aluminum alloys required for manufacturing such marine equipment can be produced in batches in China, with high quality and reasonable price.