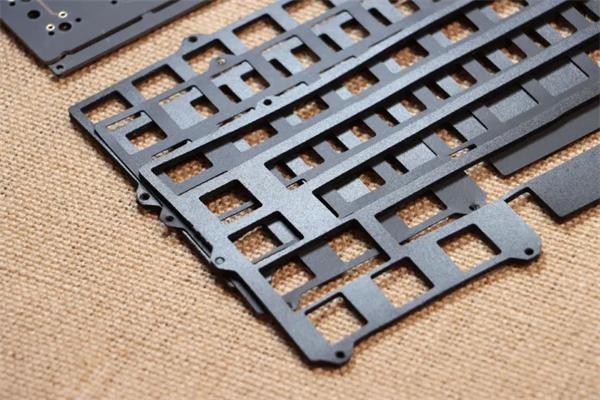

In the intricate world of technology, where precision and functionality converge, the choice of materials plays a pivotal role in defining the user experience. Enter the unassuming yet remarkable 5052 aluminum sheets – the unsung heroes behind the sleek and tactile keyboard floors that enhance our typing interactions. In this exploration, we delve into how 5052 aluminum sheets are revolutionizing keyboard manufacturing, making every keystroke a seamless symphony of precision.

1. Crafting Excellence with 5052 Aluminum:

The 5052 aluminum alloy stands out for its exceptional blend of strength, corrosion resistance, and formability. This alloy’s versatility has led it to the forefront of modern keyboard manufacturing. It’s not just about aesthetics; it’s about crafting keyboards that stand the test of time.

2. Elevating Typing Comfort:

The tactile experience of typing is a subtle art. 5052 aluminum sheets contribute to this by providing a sturdy yet slightly flexible platform for key switches. This translates into a comfortable typing experience, where keystrokes feel responsive and satisfying, whether you’re composing a document or engaging in an intense gaming session.

3. Precision in Every Key Press:

Each keystroke has a story to tell, and 5052 aluminum plays a silent role in ensuring that story is told accurately. The stability and uniformity of the aluminum sheets translate to consistent key actuation, minimizing variations in typing force and resulting in a more accurate and reliable performance.

4. Durable Design with Aesthetic Appeal:

Keyboards today are not just functional tools; they are a part of our personal style. The durability of 5052 aluminum ensures that your keyboard stands the test of time, maintaining its sleek appearance even after countless typing sessions. This makes it a preferred choice for both casual users and professionals.

5. Crafting Compact and Slim Designs:

The modern user demands sleekness and portability without compromising performance. 5052 aluminum’s lightweight property contributes to creating thinner keyboard profiles, enabling manufacturers to design compact and slim keyboards that are easy to carry and use on the go.

6. Resistance to Wear and Tear:

Keyboard floors endure constant use and occasional spills. The inherent corrosion resistance of 5052 aluminum adds a layer of protection against wear and tear, making keyboards more resilient to the challenges of daily use and maintaining their performance over time.

7. An Eco-Friendly Choice:

In a world increasingly conscious of its environmental footprint, the recyclability of materials matters. 5052 aluminum is not only durable but also highly recyclable, aligning with sustainable practices and reducing electronic waste.

From tapping out emails to crafting code, the keyboard has become an extension of our thoughts. 5052 aluminum sheets, with their strength, flexibility, and aesthetic appeal, are the unsung architects of this daily interaction. As keyboard technology continues to evolve, the unassuming presence of 5052 aluminum ensures that every keystroke resonates with precision, comfort, and a touch of elegance.