Climb ALU. takes you through The Evolution of Marine-Grade Aluminum. The ocean environment is notoriously unforgiving, presenting significant challenges to the materials used in maritime applications. Water, salt, and wind combine to create a harsh, corrosive climate that can quickly degrade poorly equipped materials.

Early Applications

In the beginning, basic aluminum alloys were adopted in shipbuilding to enhance structural strength. Aluminum, known for its light weight and resistance to rust, was an obvious choice, but the early alloys left much to be desired in terms of durability.

Alloy Optimization

As technology evolved, so did the sophistication of the alloys. Engineers began to optimize these materials specifically for the marine environment, enhancing their corrosion resistance and structural integrity.

Impact of World War II

World War II marked a turning point for the use of aluminum in naval applications. The war effort pushed the development and refinement of alloys, as the need for durable, lightweight materials became more pressing.

Post-War Developments

In the post-war era, marine-grade alloys that boasted superior corrosion resistance and strength emerged. These alloys were designed to withstand the rigors of the sea, and their application has since become standard in marine construction.

Aluminum-Magnesium-Silicon Alloys

The introduction of aluminum-magnesium-silicon alloys represented a balancing act between strength and corrosion resistance. These alloys offered the best of both worlds, ensuring the structural integrity of marine vessels while resisting the corrosive effects of the sea.

Modern Marine-Grade Alloys

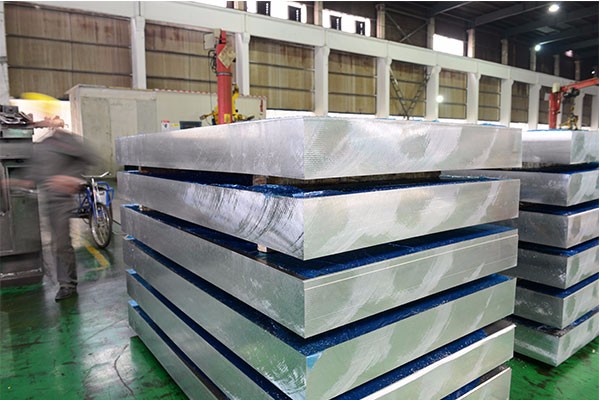

Modern marine-grade aluminum sheets, such as 5083 and 5086, stand up to the harsh marine environment with their unique properties. These alloys are engineered specifically for maritime applications and have become the industry standard.

Characteristics of 5083 and 5086

While 5083 is particularly suited for corrosion-prone environments, 5086 offers versatility and weldability. Both alloys have proven their worth in a variety of marine applications, from hull construction to deck outfitting.

Special Coatings

The use of special coatings has further enhanced aluminum’s resistance to saltwater corrosion. These protective layers provide an additional barrier against the harsh marine environment, extending the life of marine-grade aluminum.

Lightweight Performance

The lightweight nature of aluminum significantly improves fuel efficiency and overall performance of ships. This advantage is critical in an era where fuel costs are escalating and environmental concerns are at the forefront.

Applications

Marine-grade aluminum sheets are widely used in hulls, decks, superstructures, and offshore platforms. Their strength, corrosion resistance, and lightness make them ideal for these demanding applications.

Future Developments

The future of marine-grade aluminum looks promising as the industry continues to adapt to sustainability and performance demands. Engineers are constantly innovating, developing new alloys and technologies to enhance the properties of marine-grade aluminum.

The evolution of marine-grade aluminum, from basic alloys to corrosion-resistant solutions, underscores the material’s vital role in safe and efficient maritime operations. As technology continues to advance, the potential applications and benefits of marine-grade aluminum will continue to expand, firmly establishing it as an indispensable material in the marine industry.