Here’s What No One Tells You About 5083 Aluminium Alloy

Effect of annealing time on recrystallization structure and properties of 5083 aluminum alloy sheet

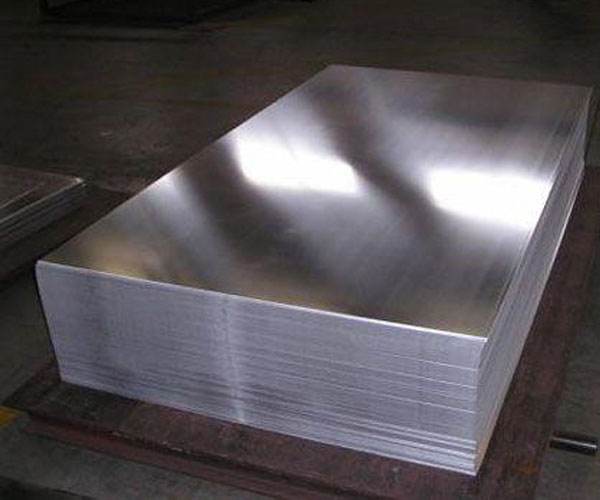

5083 aluminum alloy is a typical alloy of AI Mg series rust proof aluminum. It is used in mold manufacturing, shipbuilding, transportation, and is one of the important materials for making ship plates, ship shells, fuel storage tanks, etc In this paper, 5083 aluminum alloy sheet is taken as the research object, and the influence of annealing holding time on the recrystallization process and properties of 5083 aluminum alloy sheet is analyzed by using metallographic microscope, hardness tester, conductivity meter and other experimental equipment The experimental results show that at the annealing temperature (565 ℃), with the increase of holding time from 15 min to 360 min, the grain size of the plate increases from 23.5 μ M gradually increases to 59.5 μ m. The hardness of the plate decreased from 82.7HV to 72.5HV, and the conductivity of the plate increased from 27.2% IACS to 27.8% IACS The influence of annealing holding time on the conductivity of sheet metal is similar to that of holding time on the structure of sheet metal.

Factors Affecting the Electrochemical Properties of 5083 Aluminum Alloy

The effects of working electrode surface state, Cl – concentration and pH value on the electrochemical performance of 5083 aluminum alloy in 3.5% NaCl solution were studied by potentiodynamic scanning and cyclic voltammetry. The results show that the pitting potential becomes positive and the pitting protection potential moves forward after the sample surface is polished. With the decrease of Cl – concentration, the pitting potential Eb moves forward obviously; When the concentration of Cl – exceeds 1% (mass fraction), the influence of Cl – concentration on Eb is not obvious. The pH value of the solution and the addition of other anions will affect the pitting potential and protection potential of 5083 aluminum alloy.

Non isothermal Drawing Process of Fine Grain 5083 Aluminum Alloy

The effects of die temperature, drawing speed, blank holder clearance and lubrication conditions on the non isothermal drawing process of 5083 aluminum alloy with fine grain were studied. The experimental results show that the fine grain 5083 aluminum alloy sheet has good deep drawing formability when the die temperature is above 250 ℃. When the die temperature is 275 ℃, the limit drawing ratio reaches 2.9; When drawing at different drawing speeds with better die temperatures, it is concluded that the non isothermal drawing process of fine-grained 5083 aluminum alloy is insensitive to the corresponding strain rate within a certain range of drawing speeds, and can be successfully drawn when the indenter speed is ≤ 2mm/min. Considering the thickness of the lubricating layer and the thermal expansion performance of the material in the heating process, the optimal blank holder gap is 1.9 mm. Water based graphite is selected as the lubricant, and the drawing can be carried out successfully when the thickness of the lubricating layer reaches about 0.3mm.

Corrosion behavior of 5083 aluminum alloy in the natural environment of fresh seawater alternation

The 2-year immersion test of 5083 aluminum alloy was carried out in the natural environment of fresh water and seawater. Collect the corrosion data of test samples in each cycle, and compare the corrosion resistance of 5083 aluminum in three natural water environments. The corrosion resistance was evaluated by electrochemical methods such as corrosion potential and AC impedance. Results 5083 aluminum was severely corroded in the natural environment of fresh water alternation, and the corrosion rate was 5.3 times of that in the seawater environment and 15.8 times of that in the freshwater environment. The pitting density is the highest, and the average pitting depth is 2.6 times of that in seawater environment and 1.7 times of that in freshwater environment. Conclusion The corrosion resistance of 5083 aluminum in the natural environment of fresh seawater is poor, which is well verified by the electrochemical test results.